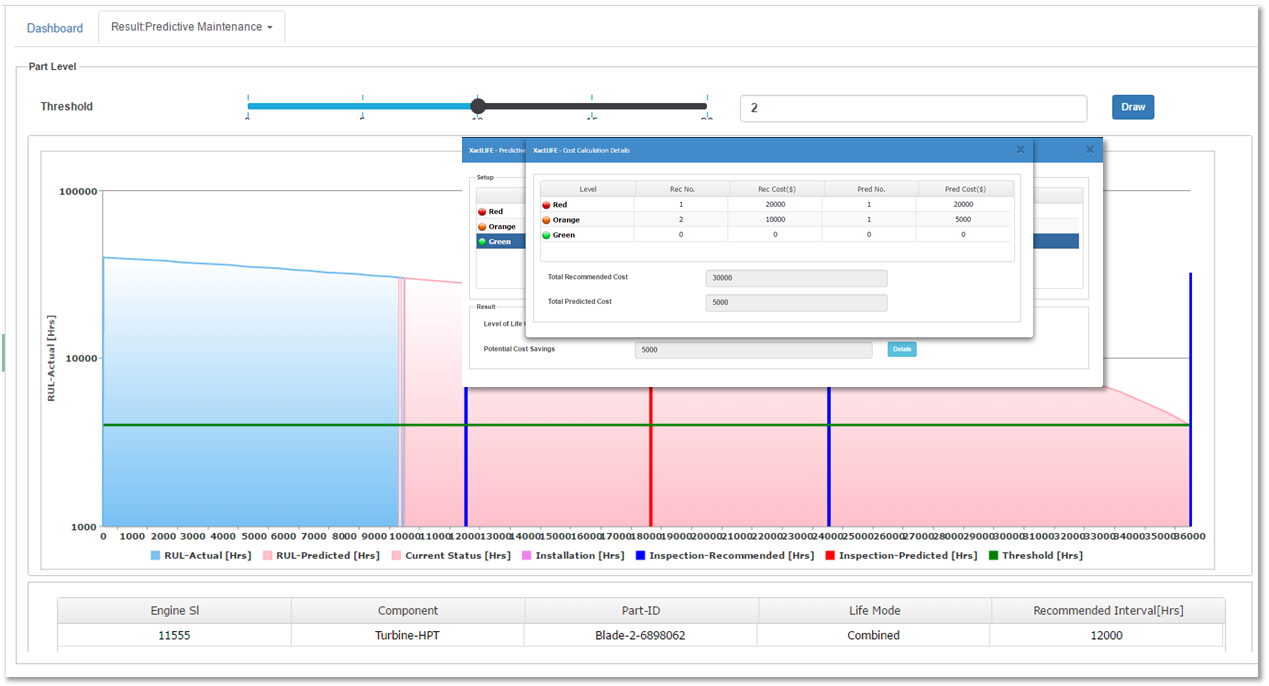

Predictive Maintenance

LPTi uses its physics based prognostics system to assess engine usage specific maintenance schedules, to quantitatively predict residual life and reliability of specific parts and to identify component level design deficiencies. Usage specific inspection intervals are predicted for hot as well as cold section parts. Prognostics analysis results are further used to make recommendations for specific inspections for a user’s life cycle management needs. LPTi experience has shown that routinely used qualitative and subjective assessment procedures such as dimensional checks, metallurgical assessment and standard inspections are not enough to ensure safe and reliable operation of the engine. User specific off-design engine operating environment, operational role and subtle changes in component microstructure play a major role in the decision making process.

Once analytical structural integrity assessment is completed, a team of well qualified engineers and inspectors is sent to the client site to inspect and reassemble the engine.

More information on Predictive Maintenance can be found here.